OUR KNOW-HOW

Py Constructeur : Material processing plants manufacturer since 1973…

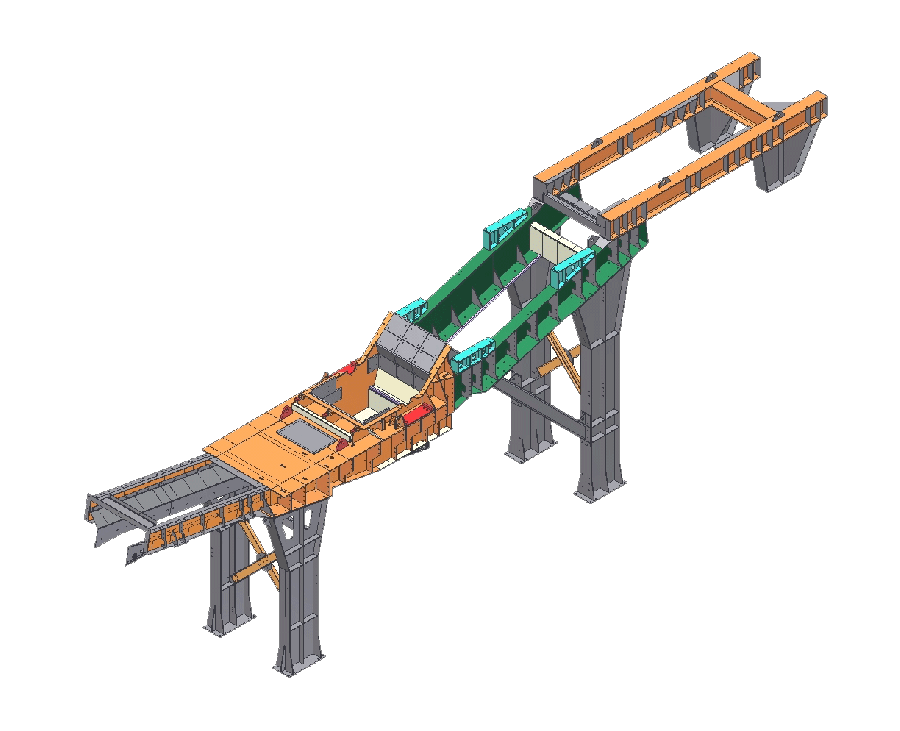

The Py society designs and produces material processing plants for crushing and recycling.

The manufacturer designs apron feeders, grizzlies (roller grizzlies, vibrating grizzlies or vibrating finger grizzlies), crushers (impact or jaw crushers) and screens, and is able to produce stationary plants as well as mobile ones.

Respond to customer needs ...

The company works directly with the customer to design the plant that will be best adapted to his specifications. That is why most of the plants designed by Py are customized. The group shares its experience and advises the customer: this is an integral part of the manufacturer work.

An engineering department at the heart of the production process ...

To meet the customer requirements, the company has a design office equipped with modern softwares (such as Autocad, Mechanical, Inventor 3 D). The technicians and engineers of this design office are a creative and an effective team (they receive a continuous training) that works closely with the producing department.

The producing department is equipped with several numerically controlled cutting machines (blowlamp and plasma cutting) whereby any shape, thickness or dimension of a work piece can be obtained.

The cooperation with the customer consists in :

- Working-out the specifications: the customer specific needs will be written.

- Advising: the constructor, Py, shares its experience and know-how.

- Materializing and approaching the solution: preliminary design.

- Describing and evaluating the retained offer.

Production consists in :

- Designing the customer’s plant : Implementation of the customer solution.

- Making a plan : general point of view and details.

- Manufacturing : Transcription in machine language.

- Machining and assembling

- Delivering and writing a maintenance notice.